LEADING, TRUSTED, NORTH AMERICAN BASED,

GLOBAL RFID HARDWARE, SOFTWARE & SYSTEM SUPPLIER

We have proudly been mentioned in hundreds of market reports, articles and news reports as a leading RFID supplier of systems

and hardware, in a variety of industries. Click on any industry below to learn more or the Report Summary.

Some Of Our Clients

Featured Products

Welcome to GAO RFID Inc., a Member of GAO Group

GAO RFID is a leading RFID and BLE company that offers one of the world’s largest selections of RFID and BLE hardware and systems across all RFID and BLE technologies. We carry a large selection of hardware including BLE gateways, BLE beacons, and RFID readers and tags that cover a broad range of frequencies and offer specialty RFID readers and tags that are designed to meet the various needs of every industry.

THREE DECADES OF INNOVATION

When choosing GAO RFID as your RFID and BLE system, hardware and software provider you gain the benefit of our experience. With 3 decades of experience and over 11,000 RFID and BLE systems deployed in more than 70 countries, we bring you peace of mind knowing our engineers right down to our sales staff are knowledgeable and can provide you with a reliable RFID or BLE system, quality RFID and BLE hardware and customized software, quicker than our competitors.

OUR RFID & BLE HARDWARE

As a leading RFID and BLE company, we are known for our large selection of RFID hardware such as tags and readers that cover a large range of frequencies including BLE and Active 2.5 GHz, Gen 2 UHF 865-868 MHz, 902-928 MHz, High Frequency 13.56 MHz, and Low Frequency 125 KHz/134 KH—all designed with the leading edge in mind to offer amazing benefits.

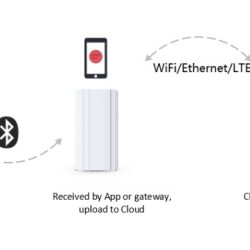

RFID READERS & BLE GATEWAYS

We carry a wide range of readers in BLE, Active, UHF EPC Gen2, LF, HF and Semi Passive and in a variety of form-factor including Bluetooth, USB, handheld, EDA / PDA, embedded, desktop, portal, multiport, barcode, integrated and much more.

RFID TAGS & BLE BEACONS

To complement our readers and gateways we carry a large selection of tags and beacons in BLE, Active, UHF, Gen2 / EPC, NFC, HF, LF and Semi Passive frequencies. Our specialty tags and beacons are designed for any business needs such as high temperature, waterproof, rugged, metal environments, hazardous environment, special requirements for medical applications and much, much more.

RFID PERIPHERALS & ANTENNAS

To enhance your RFID system, we carry a number of RFID peripherals including RFID printers, relay controllers, antennas, transmission terminals and more. RFID Peripherals and antennas can help to expand the reach of your signals, cover dead spots and integrate the RFID into machinery and more.

OUR RFID & BLE SOFTWARE

Our software is powerful and fully customizable to your needs. The core of the software is built on our “Middleware” platform which sends control commands to readers or gateways that relay tag or beacon information. With this core software we can easily adapt the software to any system need, quicker than any of our competitors.

Our software can be integrated into existing systems or tailored to a specific industry with custom reports and data tracking.

OUR RFID & BLE SYSTEMS

An RFID or BLE system is an integration of RFID readers and paired tags or BLE gateways and paired beacons and software designed to meet the need of your business or industry.

We offer a number of core systems that can be adapted to your specific needs, in your part of the world. Whether you need to control access to your building or parking lot, need to track assets in your building, monitor your employees or contractors on a job site or track items along an assembly line we have an RFID or BLE system to help you.

Tech Support

Our experienced technicians are here to support you however you need them. Whether you are a system integrator or the business owner, we are here for you!

Warranty

We stand behind our hardware, software and systems. We will provide you with a warranty and support for all our products and software.

Global

We have 4 decades of experience working with countries from all around the globe. We can handle any need, with any system, anywhere!

Quality Hardware

A great system is only as good as it’s hardware. We carry a large range of hardware for different global and industrial needs.

Versatile Software

Versatile and powerful software that can be customized to your specific needs and industry for any RFID system you envision.

Experience

We have been providing RFID hardware, software and systems for over 20 years. Let our experience find the perfect solution for your needs!